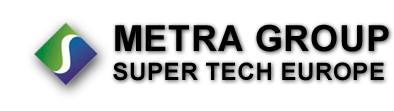

VIP is the Vacuum Insulation Panel abbreviation of English; it is one of the Insulation materials, it is by the core filling materials and vacuum protection surface layer compound and into, it effectively avoid air convection caused by heat transfer, therefore coefficient of thermal conductivity can be greatly reduced, less than 0.0020w/m.K

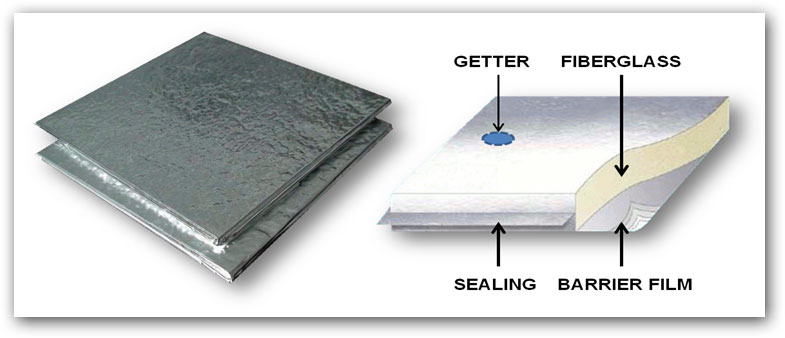

Vacuum Insulating Panel can be widely use in building, fridge, freezer, refrigerator, ultra low freezers, refrigerated containers, temperature controlled packaging, cold chain and where you need very efficient thermal insulation.

The core materials through maximize internal vacuum to isolate heat conduction, achieve the goal of energy saving; heat preservation, it is the heat preservation material upgrades, change a product, realized the heat preservation material thickness is reduced by half, energy-saving province electricity half of the effect. Currently vacuum insulating board is mainly used in building and refrigerator fields, have energy-saving, wall thin and effective volume big advantages.

Meet the future development banned CFC insulation product revolutionary requirements. It meets the future development banned CFC insulation product revolutionary requirements.

Super Tech Vacuum Insulation Panel takes highly refined fiber glass as the core material, the lacunose and reticular structure effectively increase the thermal resistance. Moreover, by using the vacuum pumping technique to make sure the vacuum degree inside VIP always keeps at a certain low level, which would maximally reduce the heat transferring between the gas molecules, therefore, finally meet the insulation requirements.

Advantages of VIPs

-More than 20 times higher insulation performance compared to conventional insulations

-Space saving and highly insulating constructions possible

-High quality and long product life time

-Covered by the high barrier film the vacuum panels are automatically protected against external humidity. This is a major problem of conventional insulations.

Core Materials

Fiber direction, structure and physical property of the core material play very important roles in producing high quality VIP with ultra-low thermal conductivity (K-Factor). In Jan, 2011, Super Tech developed the 2nd Generation VIP with K-Factor ≤ 2.0mW/m.k.

Note: Diameter of Fiberglass of the 2nd Generation VIP is approx 6~11 micron, which conforms to European Regulations, “Directive 67/548/EWG Note R, revised by Directive 97/69/EC Note Q” (the classification as carcinogenic material is not applicable to fibers with a length weighted geometric mean diameter minus two standard errors above the limit of 6 µm) Biopersistence Test Certificated by Fraunhofer Institute Hannover/Germany. Our products are certified to stringent European requirements.

The Core Materials are self-produced by six Production Lines. Thus, can ensure stable quality and prompt shipment.

The self-designed automatic Core Materials Production Line is completely controlled by the computers for the whole processes. Always focus on research and developing the Core Materials to improve VIP property. Having the ability to supply VIP with best quality and most competitive price to our customers.

VIP Specification

Thickness range: 5-35mm

Max Size: 1800 x 800mm.

Diameter of Fiberglass: 6~11 micron (which conform to the European regulations).

The K- Factor (Thermal Conductivity)at Ex-Works is ≤0.0022 W/m.K as upper and 0.0020 W/m.K as

mean value, and at customer's warehouse the K-Factor is ≤0.0021 W/m.K as upper and 0.0020 W/m.K as mean value

Density: 260-300 kg/m³

Operating Temperature: -70℃ ~ 80℃

Barrier Film/Bag

Self-produced the Barrier Film with the benefits as follows:

Can control the Pin Hole of the AL Foil.

Can control the Air Leakage rate of Barrier Film.

Ensure stable quality.

Ensure prompt shipment .

Continuously research and develop the new films to meet the different requirements of customers.

Absorbent materials

Why do need Getter inside of Panel ?

Along with the usage life time passing, the K-factor of VIP will change because the inner air pressure will rise accompaniment with below three reasons:

1) the remaining amount of residual Gas inside the panel even after the Vacuuming Process.

2) the gas released from fiberglass.

3) the external gas being penetrated into VIP.

The Getter not only can absorb moisture, but also can absorb the gas.

Using getter can help to keep VIP k-factor stable and prolong its lifetime.

Super Tech’s Getter can solve these problem.

The Comparison of Absorption Performance between Super Tech’s Getter, E-getter and Desiccant

| Item | Compostion | Capacity of Absorbing Gas | Capacity of Absorbing Moisture |

| Getter | Active metal, CaO | >99% | 100% |

| E-Getter | Little metal, Cao | A small amount | 100% |

| Desiccant | Cao | X | 100% |